Ultrasonic Cleaning Machines help you...

Clean Faster

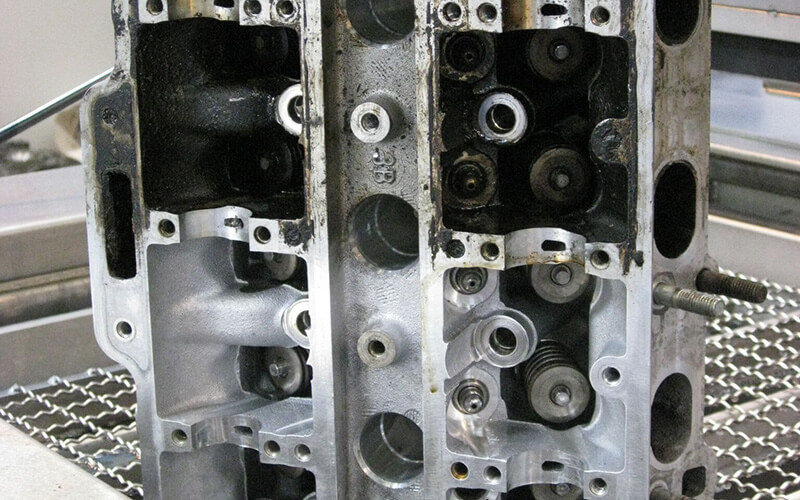

As there is no manual cleaning required, Ultrasonic can clean hard to reach internal cavities with ease and minimises the need for disassembly of components being cleaned.

Clean Consistently

The results don’t depend on the operator’s skill…anywhere the liquid touches is evenly cleaned at a microscopic level.

Cut Costs

Put the part in the tank, turn the machine on and walk away. There is no need for continuous

operator activity.

Clean Safely

Ultrasonic is safe for workers due to hands-off cleaning and reduced contact with harmful or

harsh chemicals and removal of harmful solvent vapours.

How ultrasonic cleaning works

Here is just one example of how a CleenSonic Ultrasonic Solution has helped Australian companies...

Ben Rothen

Workshop Supervisor – Rock Drills

Sandvik Mining & Rock Technology Kalgoorlie

“Since switching our rockdrill component cleaning process from manual methods to ultrasonics we’ve saved overall cleaning time on the job. the best improvement however is the cleaning job itself. The ultrasonics clean not only the external but also the internal lube areas and oil galleries that can’t be properly accessed and cleaned by manual methods which translates to better performing equipment and reliability when rebuilt. Failure rate for after service equipment is 2% which is a marked drop.

An unexpected consequence of switching to ultrasonics has also been improvement in staff retention via removing the most mundane, dirty and boring aspect of our work and replacing with a machine process the job itself has improved making it easier to retain staff.”

We can help you make you cleaning process simpler, faster and more cost-effective.

Ultrasonic Machine Range

CREST

Benchtops

Ranging from 2 - 26 litre in capacity,these units are ideal for use in Medical, Dental, Laboratory and Jewellery cleaning industries, as well as other small parts cleaning applications.

CS-Series Benchtops

Ranging from 15 - 115 litres in capacity,these units are designed for heavy industrial cleaning jobs.

ULTRATECNO Industrial

Ranging from 128 - 5,500 litres in capacity, these units are ideal for use in any industry.

Custom

Ultrasonic

We can design and manufacture any size ultrasonic machine to help you solve your unique cleaning problem.